Baffle Bulk Bags get their name from a structural component known as a ‘baffle’ present in them. A baffle is basically a fabric panel that is sewn onto four sides of the bulk bag, along the seams. There are more than one panels in each baffle bulk bag and these panels are usually absent in regular bulk bags. The addition of baffles gives the baffle bulk bags, also known as FIBC Q Bags a distinct, square shape.

If we look at the structural integrity of baffle bulk bags, the answer will be a yes. The added panels make these bags much more shapely than a regular bag, so much so that they do not bulge out like regular bags when they are loaded with materials. This gives them distinct advantages as they tend to take up less space, are easily stackable, easy to handle and form a neater load.

The baffles on these bags can be further manipulated to make them heat-sealed or sift-resistant, making them better suited for carrying agricultural products and powdered substances, respectively.

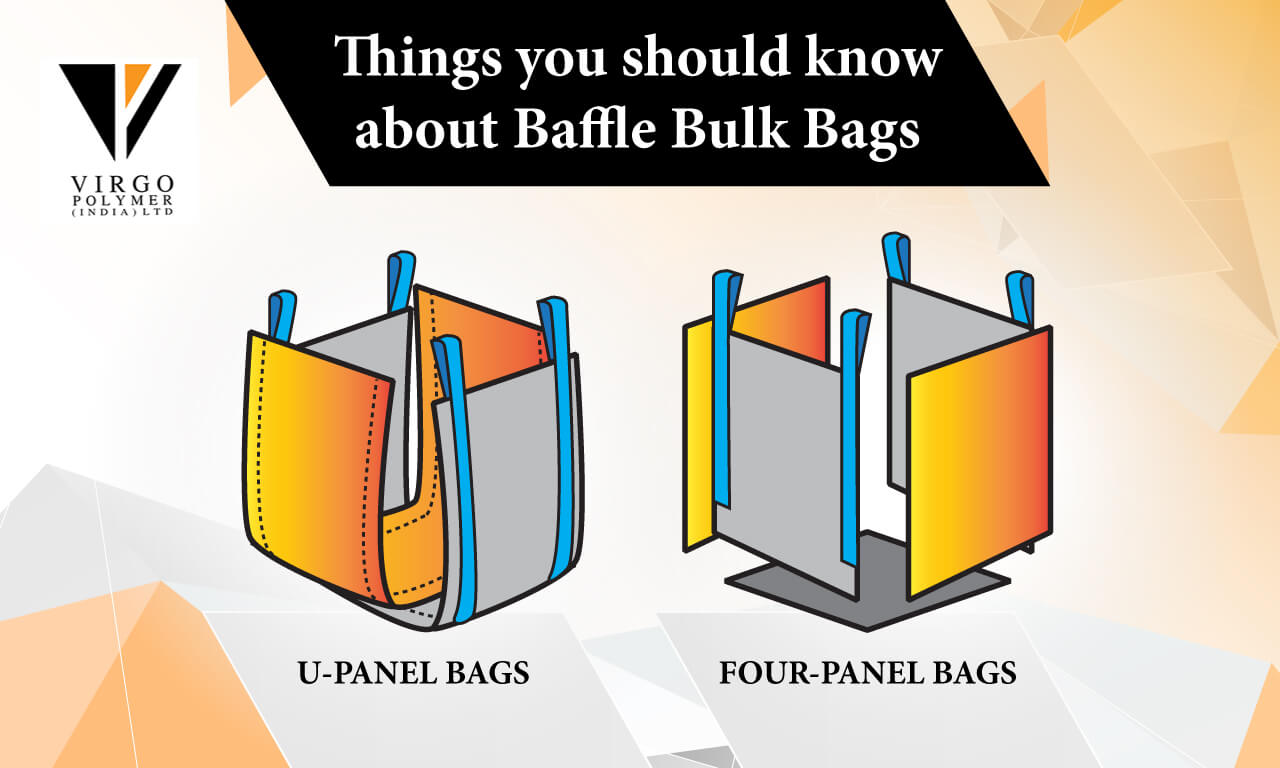

There are two major types of baffle bulk bags. These are:

If we look at the structural integrity, then 4-panel bags have proved to be better than U-panel bags. The materials are also able to flow freely to the nooks and crannies of the bag, complementing its shape and further adding stability and strength to it.

The answer to this question is that you probably might not need them if you are carrying ragged materials like rocks, etc. However, if you are thinking of storing or transporting chemicals, foods, powders, soil, etc. you might want to consider using baffle bulk bags. These bags are believed to bring down storage and transportation costs along with optimising space.

When looking for a good baffle bulk bag supplier, always investigate their industry reputation and check online for references and customer feedback. If you have any more specific questions, do reach out to us and we will be more than happy to answer all your queries.