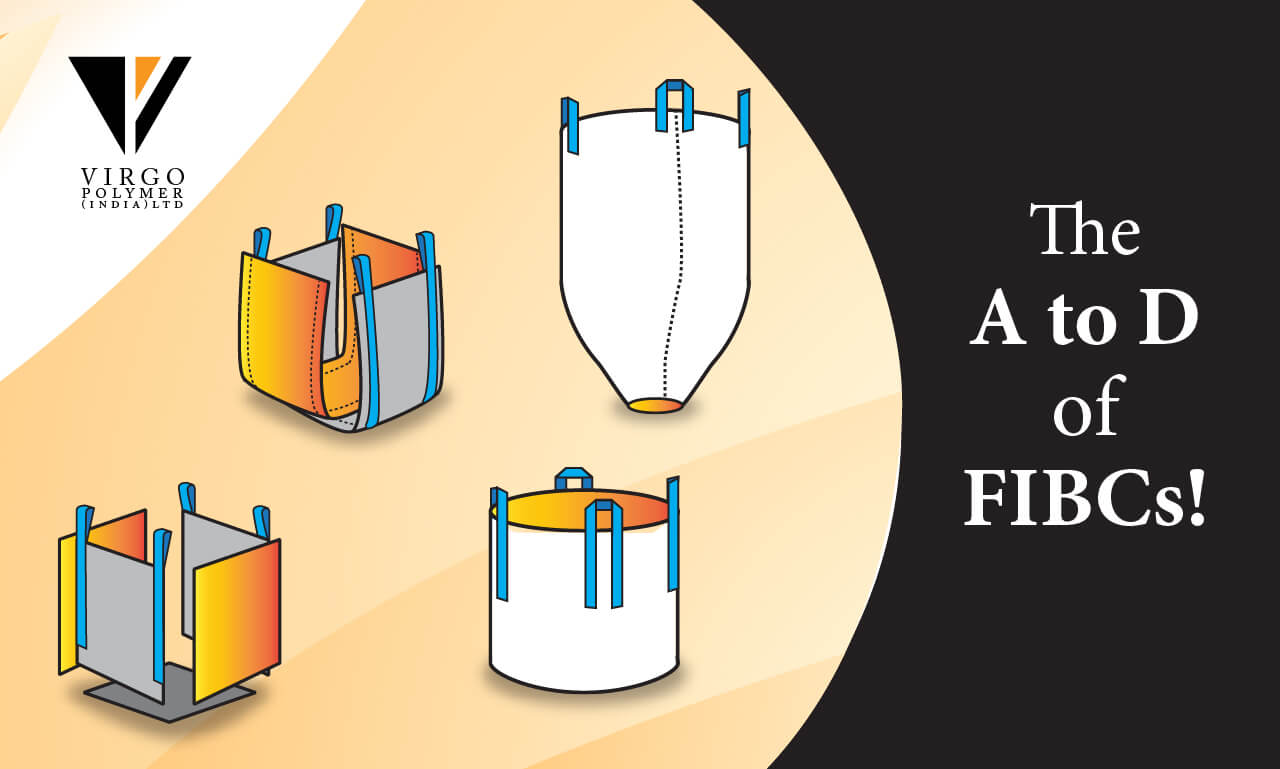

FIBCs or Flexible Intermediate Bulk Containers are used for the transportation of various types of goods over small and long distances. Since these are used to carry a wide range of materials, we have different types of FIBCs that cater to the specific needs of a particular industry. The difference can lie in the materials that are used in making them, the dimensions of the bags and their storage capacity. Depending on their features and uses, FIBCs can be broadly categorised in four different types.

Type A bags are made up of non-conductive fabrics, mainly plain-woven polypropylene. These are simple bags that do not offer any resistance to static electricity and therefore are strictly used for storing and transporting non-flammable materials. Care must also be taken to store these away from flammable solvents and gases since they can cause a security hazard. Flammable environmental conditions can also pose danger when dealing with Type A bags and therefore these must be used in areas where the atmosphere has a minimum ignition energy ≤1,000mJ.

The materials used in the making of Type B bags is the same as that of Type A bags and these too are mostly made out of plain-woven polypropylene or other non-conductive fabrics. Although these bags cannot dissipate static electricity they do have a low breakdown voltage which does not exceed 6 kV. This means that these bags are relatively safe and can be used in places where there is a chance for brush discharge. This means that although they are not anti-static per say, they can still be used to store and transport dry and flammable powders, as long as the bags don’t come in contact with flammable gases or solvents.

Type C bags differ from Type A and Type B because of the materials that are used in making these. Type C bags are made from non-conductive polypropylene materials which are interwoven with conducting threads, making a grid-like pattern. These bags must be electrically interconnected and also be connected to the earth or ground as these are being filled or discharged for utmost safety. Owing to their properties, these bags can be used for storing and transporting flammable powders, even in the presence of flammable vapours, gases or combustible dust.

Type D bags offer the highest level of safety as they are made using fabrics that not only dissipate static but are also antistatic which helps them to prevent incendiary sparks and brush discharges. These can prevent the propagation of brush discharge even without a connection to the ground or earth, making them immensely successful when transferring highly flammable materials. These bags can be used to store and transfer combustible products even in flammable environments.

Now that you know the qualities of different types of bags used in storage and transportation, you can successfully make the right choice for your materials and products, saving your company a lot of hassle and money. Contact us today for the right FIBC solutions for your business!