When it comes to finding the right flexible intermediate bulk container (FIBC) for your industrial use, there are several different types to choose from. Here’s a quick overview of each time to help you identify the right bulk bag for you:

Based on their material and type of use—primarily keeping fire safety in mind—FIBCs are classified into four main categories: A, B, C, D. To avoid accidents and mishaps, it is important to choose the right kind of FIBC from the following types:

Made from standard polypropylene, Type A bags use a non-treated insulating fabric. What this means is that the product has no electrostatic safety features and cannot prevent static electricity from being generated during filling, moving or removing its contents.

Therefore, Type A FIBCs are unsuitable for combustible or flammable materials. They can, however, be used to safely transport materials non-flammable materials, provided there are no flammable solvents/gases close to them.

Also made from standard polypropylene, Type B bags are similar to Type A bags but with one difference. The insulating fabric used in Type B bags has a low breakdown voltage, which means that they can prevent high-energy propagating brush discharges (PBD).

However, Type B bags are still susceptible to normal brush charges and are not antistatic.So while they can be used to transport dry, combustible powders (with MIE greater than 3mj), they cannot be used near flammable vapours/gases. No flammable products should be transported in them.

Type C bulk bags, popularly known as groundable or conductive FIBCs are made using non-conductive polypropylene material that is interwoven with conductive yarn. This design is suitable for controlling electrostatic charges within the bag through grounding.

The big bag is to first be electrically grounded during filling and emptying as an essential safety use process. Type C bags, when used correctly, can safely transport flammable powders and be used around flammable solvents and gases.

Known as antistatic bulk bags, Type D FIBCs are constructed from fabric that has antistatic or static dissipative properties. In other words, they can be safely used as they are designed to prevent incendiary sparks, brush discharges and propagating brush discharges - without any grounding.

However, Type D bags are not to be used on contaminated surfaces that may have conductive material (water, grease, etc). To know more about safe handling of FIBCs, click here.

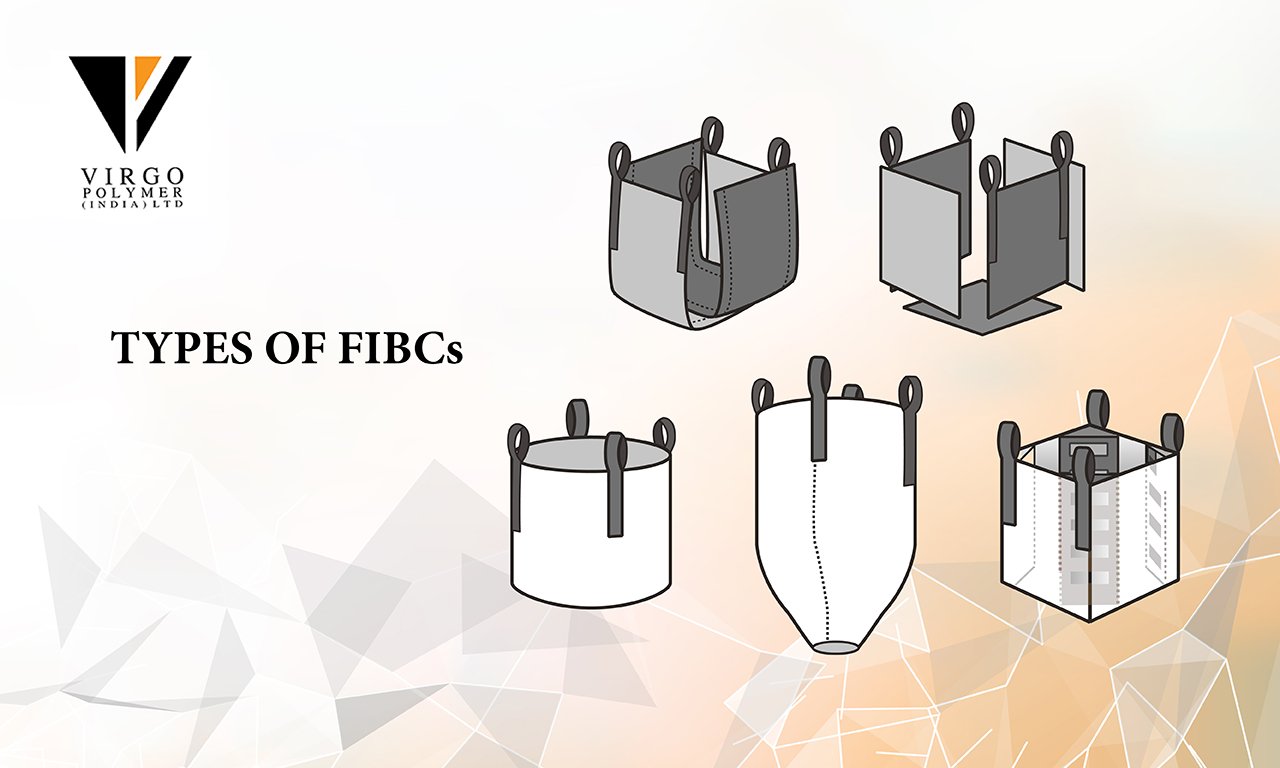

Another way to classify FIBCs is by their shape, that helps you determine the most convenient way to transport or store your materials. Although there are many more types, here are a few of the most common classifications:

U-panel FIBCs are double-seemed bags, sown along opposite sides to create a U-shaped shape. U-panels are the most commonly accepted type of FIBC because of its large capacity and flexibility in shape

Four-panel FIBCs have their four sides stitched with four different pieces of fabric sewn together on the sides and another separate piece at the bottom. This gives the bag a rather inflexible cubical shape that makes it a preferred choice for stacking and storing.

Also known as form-stable big bags, the baffle FIBC is constructed with four baffles, one in each corner, to prevent bulging of the bag when full and offering maximum stability. Ideal for lighter products, baffles are also economical due to their larger capacity.

Circular FIBCs, as the name suggests, is constructed using a single piece of cloth in a circular or cylindrical shape, with a square base. With only a single side seam, these FIBCs are easier for lifting and generally used for fine and hygroscopic materials.

Conical FIBCs are similar to circular FIBcs, but with a larger height and a tapered side that gives it a conical shape. The bottom side, when open, acts as a discharge spout for the contents of the bag - generally items like sugar and flour that can become sticky upon contact.

At Virgo Polymers, we classify our big bags based on number of loops, ventilation, type of product and so on. You can explore our range of products by clicking here .