Flexible Intermediate Bulk Containers (FIBCs) are perfect for handling, storing and transporting wet materials, because of the durability, affordability and flexibility they offer. Transporting wet materials poses some unique challenges because even the tiniest of cracks in the container can lead to contamination or loss of materials.

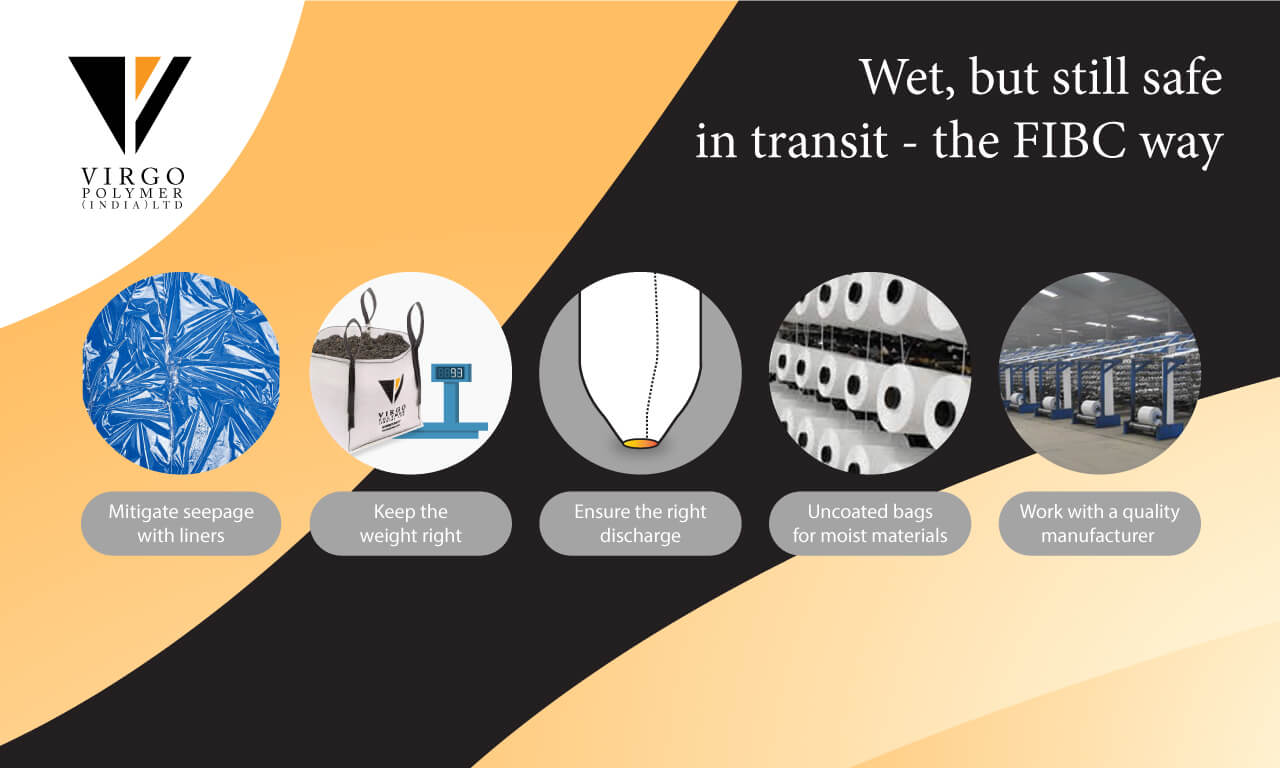

By design, FIBCs are constructed using woven strands of polypropylene, which forms a finely woven mesh. Unfortunately, these will allow liquid to seep through those tiny openings within the bag. For the best protection against seepage, one needs to add a polyethylene liner as it presents the simplest, most affordable and effective way to prevent the material from seeping out as well as water from seeping in.

Weight is paramount when it comes to transporting wet materials. Water-laden materials weigh much more than dry products, so when you take into consideration the weight of the material you are transporting, remember that you need to add in the weight of the liquid they contain. The most common Safe Working Load, or SWL for FIBCs is approximately 1000 kg. Sometimes you do get bags with SWLs of about 1800 kg. So, find a bag that can carry the weight.

Wet materials can clog the bag’s bottom discharge spout. To overcome this challenge, one can opt for bags with oversized discharged spouts or a full bottom discharge – where the entire bottom of the bag drops out during discharge (almost like a diaper, which is why it is in fact called a diaper bottom bag).

Some products are too moist at the time of storage -- industrial hemp or biomass for instance – and that could result in the chances of mold forming. For high-moisture products uncoated bags are recommended. The fabric used in uncoated bags allows the product to breathe. This is ultimately what helps to prevent mold formation. But there is no substitute for a bag liner as these can be sealed tight to prevent any moisture from leaving or entering (contaminating) the bag contents.

Ensure that you are sourcing your bags from a reliable distributor who truly understands your needs. They need to know the unique challenges associated with storing and transporting wet materials.