When it comes to storing and transporting bulk materials, safety, and efficiency are paramount. Flexible Intermediate Bulk Containers (FIBCs), have become a popular choice for such applications. FIBC tube liners are specialized inner liners that offer an additional layer of protection and convenience, ensuring the integrity of the stored contents.

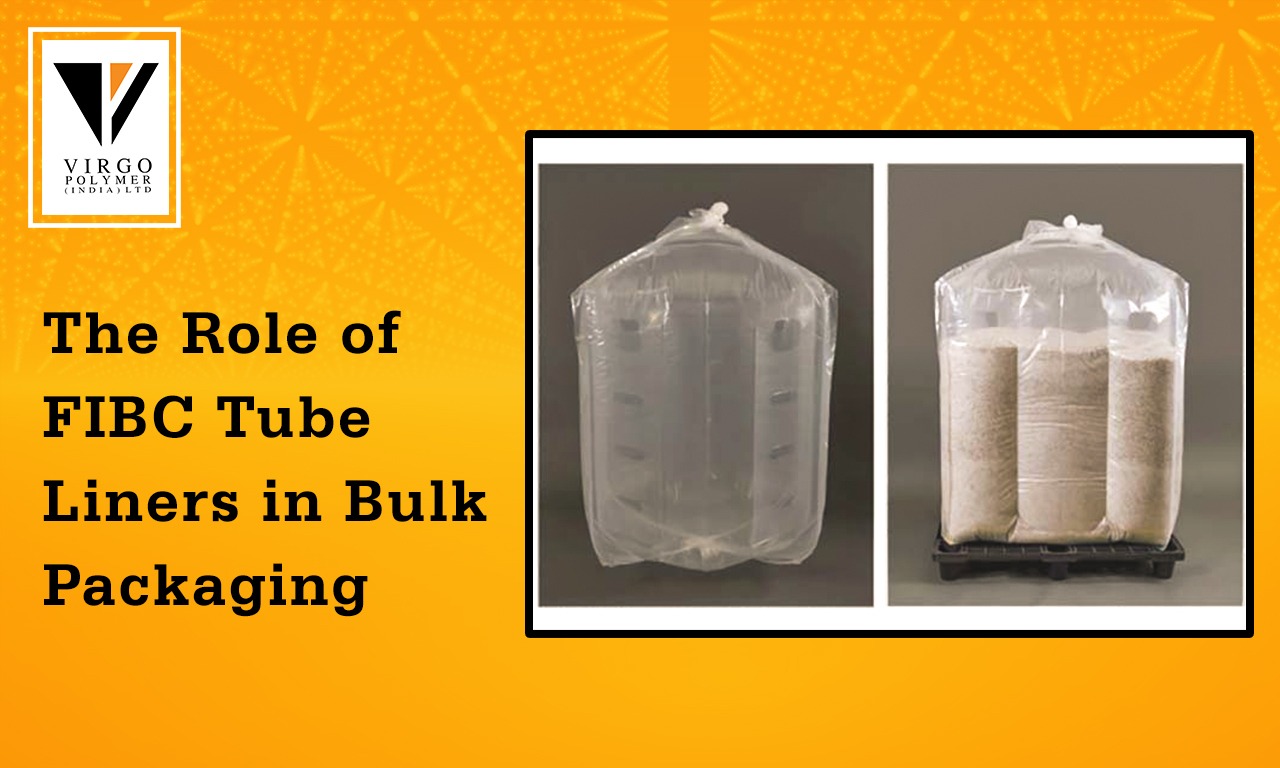

Tubular Liners or tube liners are specialized inner liners that are inserted into the bulk bags during the manufacturing process. These liners provide an additional layer of protection and convenience, ensuring that the stored materials remain secure and free from contamination. By acting as a barrier between the bulk material and the bag itself, tube liners prevent direct contact, reducing the risk of contamination during handling, transportation, and storage. They also contribute to the structural integrity of the FIBC, minimizing the chances of leakage and ensuring the containment of the bulk material.

In this blog post, we will explore the various distinguishing features and merits that make FIBC tube liners an invaluable addition to bulk packaging solutions.

Tubular liners, also known as tube liners or drum liners, are specialized plastic liners designed to fit inside various types of containers, such as drums, barrels, or intermediate bulk containers (IBCs). They are cylindrical in shape and are used to protect the inner surface of the container and its contents from contamination, moisture, and other external factors. Tubular liners have an opening at the bottom, which is a unique structural feature. Unlike other liners, tubular liners do not require a bottom seal to be cut. Instead, the end of the liner is fed through a discharge spout and securely tied during manufacturing. This eliminates the need for feeding and cutting the liner during the discharge process.

Tubular liners are commonly made from materials like low-density polyethylene (LDPE) or linear low-density polyethylene (LLDPE) due to their excellent barrier properties and flexibility.

Key Features and Benefits of Tubular Liners

Contamination Prevention: Tubular liners create a barrier between the container and the stored material, preventing direct contact and minimizing the risk of contamination. They are especially useful for storing sensitive or hazardous materials, food products, and pharmaceuticals.

Moisture Protection: By acting as a moisture barrier, tubular liners help prevent moisture absorption or leakage from the container, thereby preserving the quality and integrity of the stored contents. This is particularly important when handling hygroscopic or moisture-sensitive materials.

Enhanced Cleanliness and Sanitation: Tubular liners provide a clean and hygienic surface for storing materials, reducing the need for extensive cleaning of the container between uses. They are often used in industries where maintaining strict cleanliness standards is crucial, such as food processing, pharmaceuticals, and cosmetics.

Facilitates Easy Disposal: When the container is emptied or requires a change of contents, tubular liners can be easily removed and discarded, simplifying the cleaning process and eliminating the need for thorough container cleaning.

Versatility and Customization: Tubular liners come in various sizes and thicknesses to accommodate different container types and storage needs. They can be customized with features like gussets, spouts, or seals to facilitate the filling, pouring, or sealing processes.

Cost-Effective Solution: Using tubular liners can extend the lifespan of containers by protecting their inner surfaces from wear, corrosion, or chemical reactions. This can lead to cost savings by reducing the need for frequent container replacement.

Waste Management: Tubular liners are used for containing and transporting solid or liquid waste materials, providing an extra layer of protection against leaks or contamination.

Improved Handling and Efficiency: When filling the bag, the tube liner acts as a chute, allowing for controlled flow and preventing spillage or wastage, and facilitating even distribution within the bag. This eliminates the need for manual intervention to level the material and minimizes the risk of material segregation during transportation. During discharge,

Hygiene and Cleanliness: As tube liners are designed to be disposable, they can be easily removed and replaced, ensuring a clean and uncontaminated environment for subsequent batches or different products. This feature reduces the need for cleaning and sanitizing bulk bags between uses, saving time, and reducing the risk of cross-contamination.

FIBC tube liners play a crucial role in enhancing the safety, efficiency, and integrity of bulk packaging. By providing an additional layer of protection against contamination, moisture, and leakage, tube liners help preserve the quality of the stored materials during transportation and storage. With the right choice of liner material and responsible disposal practices, FIBC tube liners can be a valuable asset in achieving safe and efficient bulk material handling.

Curious to learn more about FIBC liners?

At Virgo Polymers, we have the expertise to assist you with all aspects of FIBC bags, from finding the ideal liner to exploring storage options and applications. As one of the leading manufacturers of FIBC bags, we provide a diverse selection of bags designed for efficient material storage and transportation.

Call +91 90030 48815 to know more or email us at info@virgopolymer.com